Hey y'all ...

Been a minute, but I wanted to update this thread....

The irrelevant part is that it was crazy hot lot year, and it's been crazy wet this winter, and the XR is a lot worse off for it. I think I may be reaching the point where it's not going to be a streetable car anymore. Most of the exterior rubber is beyond shot - windows, sunroof, everything has leaked. Admittedly, the rain this year has been extreme, but I think the damage may be done. I think '23 is the last year for this car. I'll either dedicate it to track use, or sell/scrap it. It's killing me, but I don't know what else to do.

But, I don't like to leave projects incomplete so....

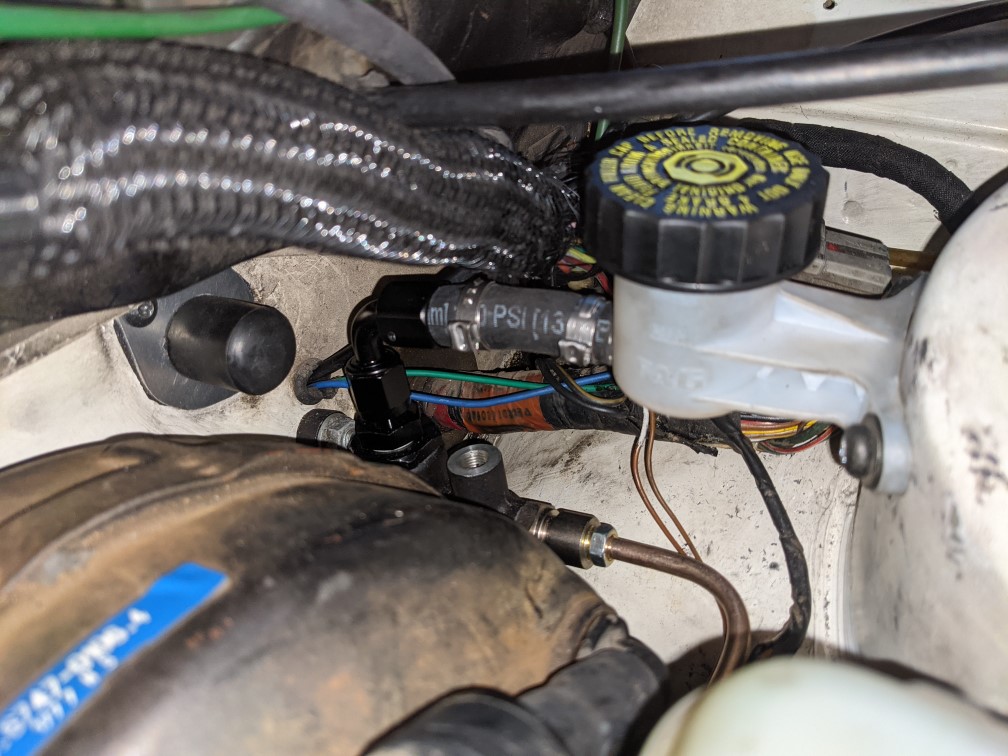

After a lot of miles, I came to the conclusion the clutch was just no good. The pedal effort was starting to be a problem, and the clutch travel was so short that traffic was borderline unbearable. I yanked the Tilton .810" master cylinder and replaced it with a Wilwood .750" master cylinder:

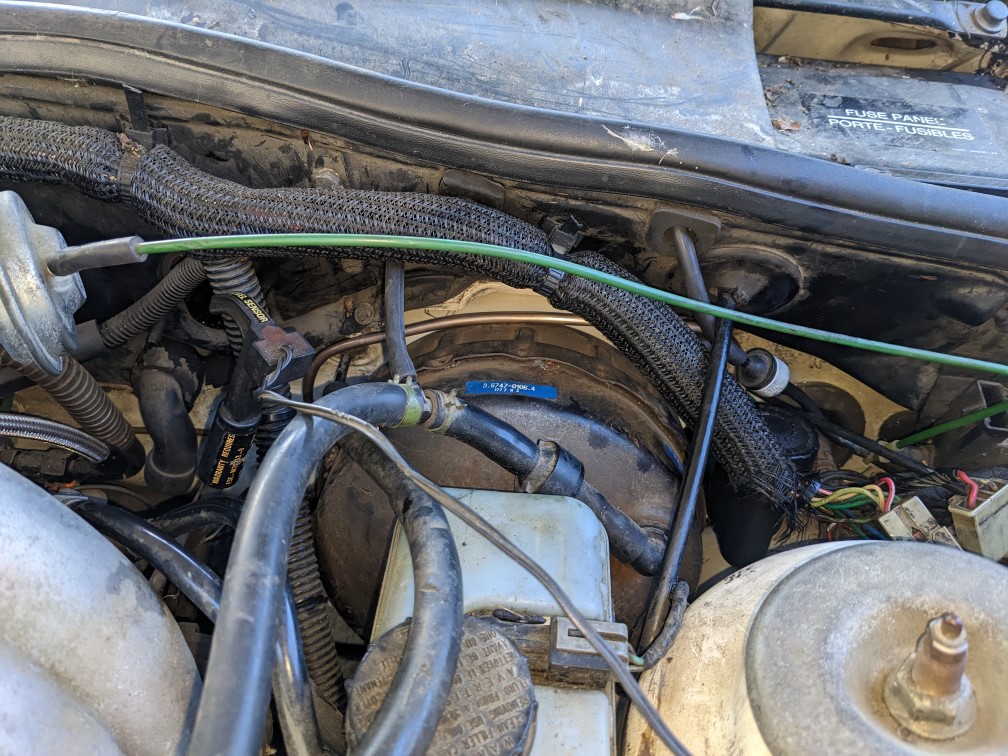

The Wilwood has an integrated reservoir, which is very poorly located... but workable. How often are you in a clutch reservoir anyway? The other annoyance with this MC is that the outlet is on top, facing the firewall, so now I have a goofy clutch line:

I do not like that it goes up at all, because bleeding is worse, but the smaller bore and extra 1/4" of travel makes a difference. I don't have many miles on it, but clutch effort is substantially less, and it's much easier to modulate. I cannot find an SAE-style master with more travel, so this damn well better work out.

Fortunately, both the Tilton and Wilwood ARE SAE-style, so it's basically plug & play. The flange is the same, the thread on the pushrod is the same. It was a one hour operation swapping them and making a new hydraulic line.

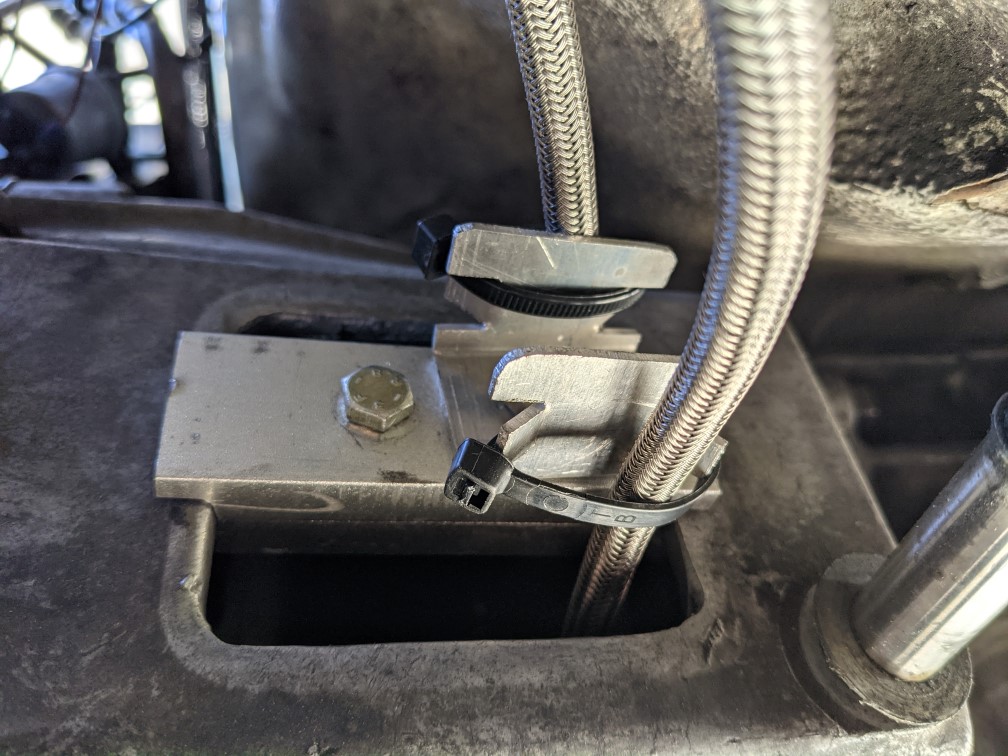

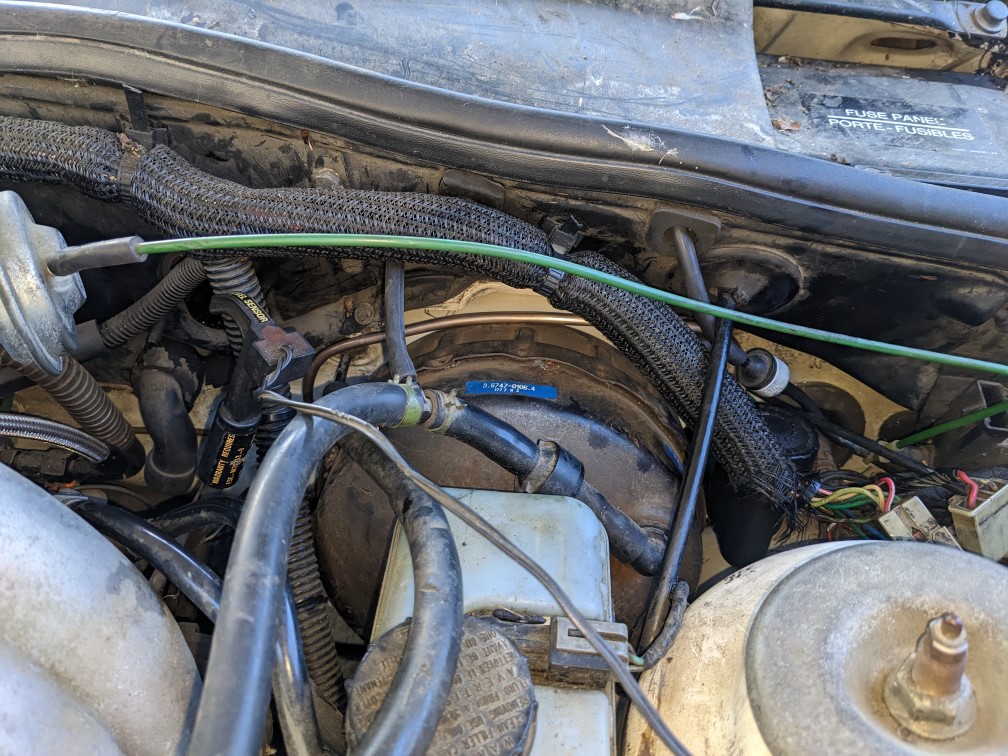

Thread-related, the motor mounts in the car was awful. Simply unbearable vibration. My SPG has solid motor mounts:

and was less annoying to drive! I don't have an explanation, but it made me even more irked at the whole motor mount thing. Maybe what I got shipped were solid rubber mounts or maybe they were old stock and dried out, IDK. I jumped on rockauto, bought a pair of DEA hydraulic mounts for a T-bird, and bolted them in. While doing so, I tapped the new mount for an M10-1.5 thread and used 10.9 bolts instead of the 8.8 studs. I realize the studs are safer, but 8.8 hardware on motor mounts gives me the willies... so 10.9 bolts and threadlock. I'll check back on them in a few hundred miles and make sure they're still tight.

In case anyone cares, those bolts are M10-1.5 x 70mm with an extra thick fender washer. This yields about 12mm of engagement in the motor mount, which is maximum. Any longer starts digging into the rubber of the mount. The old studs did not have this much engagement, for whatever that's worth. I'll tell you, installing mounts without that top stud is cake! Maybe worth the price of admission!

No more cabin vibration, better clutch feel... we'll see how 2023 goes.